REGIONAL ACTION PLAN SLOVENIA

D.T3.1.5 UM, AE-ROBO May 2022

PDF version you can download here.

Precision agriculture

Precision agriculture (PA), through the use of innovative technologies, is a farm management concept that can be used to increase long-term efficiency, manage uncontrolled change and reduce negative impacts on the environment. PA uses new technologies and innovations, combined with site-specific agronomic expertise. Pa maximizes production efficiency and increases the quality of agricultural produce without increasing environmental burdens. A is defined as an integrated approach to agriculture, which is not only synonymous with precision agriculture technologies (PATs) but is also a systems approach to the whole agricultural production. PA has been developed through the expertise of different disciplines.

The main (overarching) objective is to reduce decision uncertainty in agricultural work processes by focusing on better understanding users and managing uncontrolled change. Suppose variability in the field is a significant source of uncertainty. In that case, it is essential to manage appropriate PA processes that can respond to variable factors at the level of spatial and temporal distribution.

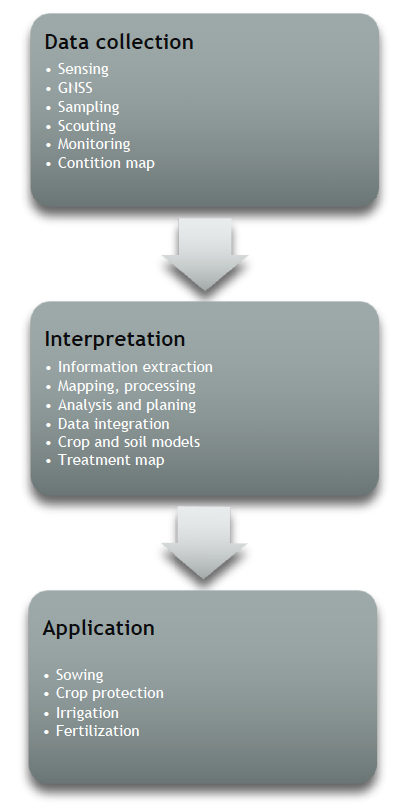

The formation of the PA cycle is further defined by Comparetti (2011), who defines PA methods in the following stages (shown in the following diagram):

- Data collection (measurement of spatially variable soil, crop, or yield parameters within the field and monitoring of local weather conditions)

- Interpretation (integration and mapping of input/output applications with different models)

- Application (application of variable inputs based on the results of data processing)

Precision agriculture technologies, through sophisticated analysis of production resources, create significant opportunities to improve the efficiency of farming operations while contributing to solutions for sustainable agriculture and the environment. The availability of new technologies - farm machinery automation, geospatial tools, sensor and information systems, and others - enables precision farm management. In addition to generating accurate and integrated data sources needed for spatial variability decisions, PATs contribute to data diagnostics that link mapped field locations to the most appropriate decisions on sowing, fertilizer inputs, irrigation, crop protection products, crops, etc. They make it easier to manage inventories and account for costs by automatically recording input usage and tracking data

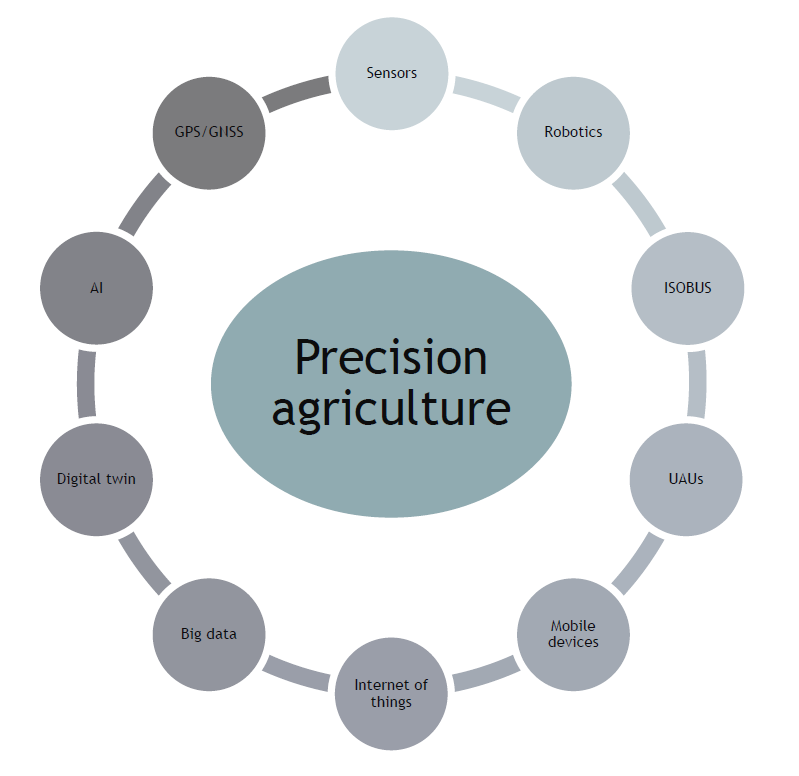

There is no single typology of PATs. However, it can be defined as follows.

- GPS (global positioning system)

- Geographic information system (GIS)

- Sensor systems

- Variable rate technology (VRT)

- Yield mapping (YM)

- IoT (Internet of things)

In the diagram below, we have outlined some of the basic components of precision agriculture technologies.

Precision agriculture has enjoyed a remarkable expansion and popularity in some parts of the world, especially where more intensive farming practices are present. Farms use advanced machinery in a wide range of agricultural sectors. The North American market plays a leading role in PA. The European, Asian, and South American markets also have a significant share. Europe's innovative potential in PA is great and an important lever for agricultural prosperity. In Europe, precision agriculture market was worth USD 2.21 billion in 2021 and projected to grow at a CAGR of 13.2%, to reach USD 3.18 billion by 2026.

Characteristics of Slovenian agriculture

Slovenia is one of Europe's smaller countries, both in terms of land area and population. According to the OECD typology, Slovenia has intermediate (27.2%) and rural regions (72.8%). More than half of Slovenia's land territory is covered by forests, and 34% of its land area is predominantly agricultural. Slovenia is characterized by a dispersed and sparse population and a large number of small settlements. In Slovenia, agriculture with hunting, forestry and fishing contributes 2.3% (2019) to total value-added and 6.9% (2019) to full employment. The share of employment in agriculture is a declining trend and thus decreases year on year.

In Slovenia, decreasing the number of agricultural holdings continues, while the average size of a farming holding increases yearly. On average, a large agricultural holding in Slovenia cultivates 7.0 ha of agricultural land and manages an average of 5.6 ha of forest. Compared to the EU-28, Slovenia still has a very unfavorable size structure of agricultural holdings. The average age of farm owner (manager agricultural holding) in Slovenia amounted to 57 years (2016), which indicates a markedly unfavorable age structure in agriculture. In 2019, 745 companies were operating in the food processing industry, employing 14,627 people. Value-added was EUR 604 million and value-added per employee was EUR 41,270 EUR. Grassland is the most predominant area (84%). Then arable (9%), orchards (intensive and extensive - 4%), vineyards (1.4%), and vegetables (0.7%).

Income in Slovenian agriculture is among the lowest in the EU and represents only around 20% of comparable income in the whole economy. Non-agricultural sources of income are decisive for farming on low-income farms, which can represent a significant part of the income on small farms. Such a poor income situation is the unfavorable structure of Slovenian agriculture with an average of small farms, a large share of land in LFAs, a large percentage of absolute grassland, a large share of non-specialized and self-sufficient farms. Existing processes of Slovenian restructuring agriculture in the direction of increasing income are too slow. Subsidies (direct and LFA payments) are a significant factor in Slovenia, at least partly improving the lower-income situation. Specific agricultural sectors (arable crops, other permanent crops, mixed farming, other grazing livestock), economic farm size (up to EUR 50,000 standard income), and farm location (in LFAs) would generate negative value-added if they did not receive subsidies. Uncertainty about incomes and low productivity leads farms to stagnate investment and, in the long term, to lose competitiveness. Instability is a significant problem in Slovenian agriculture. Fluctuations in prices and/or agricultural volumes can cause liquidity problems for farmers. Uncertainty about incomes and low productivity leads farms to stagnate investment and, in the long term, to lose competitiveness. Uncertainty also causes stagnation or even contraction of agricultural production.

Multiple factors affect the competitiveness and productivity of Slovenian farms; 73.7 % of farms are located in less-favored areas (of which 73.3% - are mountain areas, 10.8% - are areas with natural handicaps, 15.9% - specific constraints), climate change (storms, frost, drought, floods, strong wind, ...) and role of technology (state of machinery/equipment, digitalization, knowledge and innovations in relation to precision agriculture technologies).

There is a strong divide between productivity indicators between EU-27 countries and Slovenia; on average, the divide in EU countries is caused by the introduction of new technologies that substitute the workload. In Slovenia majority of the work is done by manual labour (avg. size 7 ha), and lacking new technology. Farms located in mountain areas face special challenges, shorter vegetation periods and lower income per farmland. Due to the limitations, these farms primarily focus on animal production. An additional factor that limits the possibilities on these farms are the inclinations of farmland that require expensive special-purpose machinery.

Promoting knowledge, innovation, and digitalisation in agriculture in Slovenia

There are several research and training institutions working in the field of Slovenian agriculture and forestry institutions. Public services have been working for decades for the advancement of agriculture and forestry, for better performance of professional tasks in agriculture (livestock farming, crop production, forestry, genetic). Access to formal as well as non-formal education is good. Identified needs and necessary actions in this area:

- Strengthening capacity building and knowledge transfer.

- Strengthening cooperation between the research sphere, consultants, and end-users.

- Strengthening research and development, innovation in agriculture, forestry, and food.

- Retrieved from agricultural advice.

- Digitalisation in agriculture, food, forestry, and rural areas.

- Strengthening digital competences.

Analysis of the factors impacting on the adoption or non-adoption of precision agriculture technologies

The awareness and implementation of new technologies in agriculture, which also includes PA, is reflected in numerous factors in a specific smaller area, such as on a farm, at national or even international level. Based on the literature reviewed, the table below shows the most influential factors.

| Factor | Description |

| The personality and family structure of the farm owner | Age, education, computer usage, skills |

| Features of the farm | Farm size, farm type, ownership, specialization |

| Social interactions | Local cultures, local cooperation, human relations – attitude of trusted friends |

| Economic factors | Return on investment time, the possibility of rental technologies, technology costs |

| Policy support | Legislation, measures, strategic plans, vision |

| Supporting institutions and firms | Numbers of supporting institutions and firms |

| Multidisciplinary cooperation | Active participation of all stakeholders in PA |

| Features of the technology | Availability of technologies, easiness of use, systems compatibility |

SWOT analysis of precision agriculture in Slovenia

With the help of the SWOT analysis, we summarized the current situation and guidelines for the development of precision agriculture in Slovenia in four aspects (advantages, opportunities, dangers, shortcomings). The purpose of the analysis is primarily to assist decision-makers in strategic decisions regarding precision agriculture in the future and to assist in further research in this area. The SWOT analysis included summaries of the state of EU and Slovenian policy measures, characteristics, and structure of Slovenian agriculture, as well as the results of a survey obtained in this project (Transfarm 4.0) on the topic of precision agriculture.

| Strengths | Weaknesses |

| Farm owners are aware of the potential of PATs

(precision agriculture technologies). More than three-quarters of farm owners are already educated about PATs. There is more and more research development and talk about PATs. |

PATs require a high initial investment.

Complex and sometimes unreliable PATs. |

| Opportunities | Threats |

| Accelerate sustainable agriculture through

technological development. Interaction of farm owners with ideas / solutions. Optimization of agricultural work, processes, reduction of environmental impact, management of uncontrolled changes and support decision-making. |

Questionable willingness and maturity of farm

owners for the implementation of PATs. Complex quantification of PATs advantages. Questionable knowledge about open opportunities or fear of farm owners’ interactions. Prejudices of farm owners about the maintenance costs of PATs. |

Slovenian Smart Specializations Strategies (S4, Slovenian S3)

Slovenia, as one of the smallest EU member states, has limited resources, capacities, and capabilities, so largely dependent on intensive investments, high risks, high responsiveness and uniqueness, originality. This was considered when the Slovenian Smart Specialization Strategies (therefore S4, and not S3) were drafted with the goal to enhance cooperation between Slovenian innovation stakeholders that operate in specific priority areas. One of the first task to shape S4 was to open a public discussion by attracting companies, research organisations, start-up community, social entrepreneurs, artists, innovators, scholars, students, and others to participate in entrepreneurial discovery process and to identify priority areas, conceptual leaders with the government as the facilitator. The entrepreneurial discovery process made possible that stakeholders operating in a specific S4 priority area have recognised the need for comprehensive and systematic cooperation amongst themselves and with the government.

According to the identified priority areas from the draft of S4 Slovenia launched a public call in 2016 to form nine Strategic Research and Innovation Partnerships or SRIPs. These include (with examples):

• SRIP Factories of the Future Demo project like GOSTOP (Building Blocks, Tools and Systems for the Factories of Future) include the development of new products and technologies, which will lead to the set up of uniform integrated systems, needed by big production companies and provided by SMEs.

• SRIP Health-Medicine Project Medical Valley describes a new university campus focusing on pharmacy, biomedical technology, biomimetic and biotechnology, included in a new regional proton radiation therapy cancer treatment centre.

• SRIP Materials as End Products Formed a cooperation between its members with the goal to the development of new joint developments. like so-called 'hot work tool steels', new light-weight high-strength construction steels, new (recycled) Al alloy and new multicomponent magnetic material based on thermosets.

• SRIP Mobility Formed EDISON (Eco Driving Innovative Solutions and Network) partnership which focuses on the development of inductive wireless charging systems for electric vehicles, the development of new drives and applications and platforms for electro mobility.

• SRIP Networks for the Transition of the Circular Economy Formed a strategic R&D program named Cel.Krog that aims to exploit the potential of biomass for development of advanced materials and bio-based products.

• SRIP Smart Cities and Communities Established the Digital Innovation Hub Slovenia, a national one-stop-shop to help Slovenian companies to become more competitive in respect to processes, products or services using digital technologies.

• SRIP Smart Buildings and Homes On of the activities involved Wood Chain demo project which development of a new terrain tracking and monitoring service, by using orthophoto images, that enables digital verification of construction, with the concept of 3D design of the environment.

• SRIP Sustainable Food Production Established a completely new cooperation between stakeholders in dairy processing sector, meat sector, fruit sector and cereal sectors to form new value chains.

• SRIP Sustainable Tourism Formed Tourism 4.0 demo projects, focused on creating a new format of dynamic collaboration system, with applications, services and processes built on real-time tourist needs and wishes. SRIPs were formed to support investment and intellectual potential of Slovenian stakeholders and were shaped as a long-term quadruple helix bottom-up partnerships, that brings together dynamic companies (like SMEs), research institutions, innovation users and also State and municipalities that operate in a specific S4 priority domain. In three years more than 780 stakeholders joined SRIP partnerships, out of which 83% were enterprises (79% SMEs).

S3 / S4 in Respect to Precision Agriculture

By definition precision agriculture represents an interdisciplinary approach to farming. By applying technology, the farmers / producers can optimize the yield of the production and minimize the input resources, maximizing the profit in return. By recording, measuring, and observing with relative readings the variability of the crops is detected, followed by actions to treat it, if necessary. These include soil cultivation, sowing, spraying, fertilization and other. By applying the right treatment in the right time frame, the producer will gain economic and ecological improvements by: maximizing the quality of the crop, reduce input resources, like seeds, chemical products and fuel, it will minimize the possible negative environmental impact, reduce the work hours needed and (auto) produce a complete production documentation. Although the importance farming has in Slovenia, the Slovenian’s smart specialization strategy S4 does not address precision agriculture with a dedecated SRIP, instead its support can be directly or indirectly found in already existing SRIPs. The two SRIPs that are directly linked to precision agriculture are SRIP Sustainable Food Production and SRIP Factories of the Future.

• SRIP Sustainable Food Production

SRIP Sustainable Food Production (SRIP HRANA) unites agriculture holdings, companies, cooperatives, research institutions, investors and other interested parties toward joint research and development activities to improve agri-food sector development. This involves becoming a national contact point for companies and research institutions to promote networking and cooperation. The SRIP activities are co-funded by the Slovenian Ministry of economic development and technology and the European Regional Development Fund.

SRIP Sustainable Food Prodction defined an action plant that is formulated on the five action pillars that summarize the five objectives of the SRIP strategy. Besides these five action pillars, three horizontal areas that need to be improved have been identified. This are human resource development, internationalization and Information and communication technology (ICT). They are incorporated in to the 5 action pillars. These five action pillars are:

AP1 - INGREDIENTS AND SUSTAINABLE USE OF RESOURCES

The first action pillar is related to the SRIP Network for the transition the circular economy. It focuses on the sustainable and efficient use of resources for sustainable vegetable food production and processing and for sustainable livestock production.

AP2 - SMART PROCESS PLANNING AND PROCESS CONTROL

Smart process planning and process control is related to SRIP Smart Cities and Communities, and horizontal ICT network. It focuses on optimization of agro-food processes based on automation, digitalization, and robotization.

AP3 - ADVANCED EQUIPMENT AND TECHNOLOGIES FOR SUSTAINABLE FOOD PRODUCTION AND FOOD PROCESSING

The third action pillar is related to SRIP MATPRO and focuses on the development and use of advanced technologies in the production and processing of food to produce interesting, competitive, and innovative production of food products, with food safety, improved nutritional value and higher functionality in mind.

AP4 - HYGIENE, SAFETY AND QUALITY OF FOOD

The fourth action pillar focuses on ensuring food safety, detecting food fraud at all stages of food production and processing by development of new innovative products and services for ensuring the safety and quality of finished products.

AP5 - FOOD, NUTRITION AND CONSUMER

The fifth action pillar is related to SRIP Health-Medicine and SRIP Sustainable Tourism. It focuses to develop a system that will lead to the innovation development of the entire agrofood chain by promoting the invention of functional food products for individual target groups.

• SRIP Factories of the Future

SRIP Factories of the Future is the largest SRIP, lead by Jožef Štefan Institute. It is divided into four clusters:

- Advanced technologies cluster (led by Jožef Štefan Institute),

- Smart factories cluster (led by Chamber of Commerce and Industry of Slovenia).

- Systems and control technologies cluster (led by KC STV),

- Toolmakers cluster (led by Tecos).

The SRIP FoF is devided into the following pillars.

AP1 - ADVANCED SENSORS

This pillar addresses the importance of advance sensors in autonomous and smart systems. And includes the following focus areas:

- Advanced micro and nano sensors for process control - to increase the competitiveness of end products.

- 3D sensor systems - to increase the competitiveness of end products.

- Smart nano/bio/chemo sensors in the environment, industry, and medicine - to increase the competitiveness of end products.

AP2 - INTELLIGENT LASER SYSTEMS

Laser Systems play an important part in research and development sector, with the largest production of solid laser systems per capita. This pillar includes the following focus areas:

- Special laser sources - to develop new laser sources.

- Intelligent laser systems for the digital processing of materials - to develop high-tech additive laser systems for the semiconductor industry.

- Smart medical laser devices - for the use of laser sources in medicine (regeneration, therapeutics, dermatology).

- Next generation optical fibres - to develop special active and passive fibres for IR and UV.

AP3 - INTELLIGENT MANAGEMENT SYSTEMS FOR FUTURE FACTORIES

Future Factories promise a better-quality products, better efficiency, time, and cost savings in real time. An important part of this are the Internet of Things (IoT) and Services. This pillar includes the following focus areas:

- Smart actuators - for complete surveillance and cost optimization.

- Distributed control systems and IoT - device and sensors control in industrial processes using IoT.

- Intelligent Production Management Systems (MES-MOM) - to develop advanced software solutions for management and decision support.

- Diagnostics, prognostics and self-maintenance of smart machines and processes - to develop

advanced software solutions and modules for predictive maintenance of machines and devices.

- Development of modern tools and building blocks for the management and control of systems and processes - to improve lithographic procedures in microelectronics with the appropriate control of the mass production process.

AP4 - NEW MATERIALS

New materials enable technological advancement in all areas of society and is the basis for its sustainable development. The pillar includes the following focus areas:

- Magnetic materials with a minimum quantity of rare earths - to develop and production of magnets, that will replace the need to use rare earths.

- Environmentally friendly materials for protective elements in electrical engineering and electronics - to increase the production and sales of products to improve the content of materials.

- Functional coatings - inclusion of new materials into products.

AP5 - ROBOT SYSTEMS AND COMPONENTS

Represents one of the fundamental pillars of Factories of the Future. With new intelligent sensors, actuators and other advanced robotic components, the flexibility of the robots will increase. To achieve this, the following focus areas have been defined.

- Manufacture of new robots - with the aim to put Slovenia on the global map of robot and robot parts manufacturers. This includes the development of new agricultural robots driven by artificial intelligence.

- Innovative intelligent and sensor supported robot applications (advanced mechanical vision) - to introduce new sensory system, such as machine vision to improve the flexifile and autonomy of robotic systems.

- Intelligent sensors and actuators for the use of robotics - to produce and market advance components of state of the art robots.

- Development and marketing of flexible and cooperative robot cells - to use superior multidisciplinary technological knowledge to use robotic building blocks into automated cells and lines.

AP6 - SMART FACTORY

This pillar joins all vertical value chains and horizontal networks in the area of SRIP FoF and wider. It's an umbrella like process with defined contact / control points that will make the digitalization the most important process in companies making an increase in the added value of its processes. It includes the following focus area:

- Optimal (individualized) comprehensive solutions for the implementation of smart factories - defining the implementation of the Smart Factory and establishing a value chain to transform the cooperation with the partner company.

AP7 - SMART MECHATRONIC TOOLS

Complex mechatronic systems are making possible to build advanced and smart industrial tools. These systems are used for monitoring, regulation and communication between devices and external devices / machines to improve the usefulness of this smart machines. This pillar includes the following focus areas:

- Smart mechatronic tools - used to increase smart tools investments for tool makers.

- Linking simulation tools with manufacturing machines to optimize production processes

- used to simulate and optimize the production process, to minimize defective products and to ensure the production with as short as possible deadlines.

- Advanced production process and prototype technologies - to merge existing development centers into one, supported by Sloveninan manufacturing industry to support SMEs.

In addition to this action pillars six horizontal areas have been identified, which provide key technologies. These are:

- Management Technologies

- Modern Technology for Materials

- Nanotechnology

- Photonics

- Plasma Technology

- Robotics

Interviews with S3 managers – SRIP Factories of the future

Meeting date: 1st of June 2022: 9.00 - 10.30

Zoom platform for online meeting

Attandees:

Živa Antauer - SRIP TOP

Jurij Rakun – UM, FKBV

Erik Rihter – UM, FKBV

Peter Lepej – AE-ROBO

Agenda of the meeting:

To discuss the S3 regional specializations managers regarding the current and future inclusion of precision agriculture in SRIP TOP (Factories of the future); to identify the links between innovation strategies and the agricultural production sector, to promote technological development, implementation of regional innovations, support for the agricultural production sector and support for the education system with the possibility of directional training for agricultural needs.

Conclusions:

Agriculture is not the main sector

SRIP TOP is one of 9 designated S3 / S4 areas in Slovenia. It does not support agricultural sector directly, but indirectly by supporting other horizontal areas such as smart plasma and (agricultural) robotics. In addition to this AI horizontal area could support precision agriculture in the future.

How can SRIP TOP support knowledge transfer in the field of PA and wider?

Part of SRIP TOP’s work is to offer support, which also includes organization of different events led by GZS (Slovenian chamber of commerce), TECOS (industrial cluster) and Jozef Stefan Institute. This events also support knowledge transfer, indirectly to the field of PA.

System of technological incubators and laboratories for Industry 4.0 companies

SRIP TOP itself is not an incubator or does not provide one, but its partner organizations are, including: Pomurski tehnološki park, Savinjsko – Šaleška razvojna agencija SAŠA, Podjetniški inkubator Novo mesto, CS Škofja Loka and others.

System of technological incubators and laboratories for Industry 4.0 companies SRIP TOP itself is not an incubator or does not provide one, but its partner organizations are, including: Pomurski tehnološki park, Savinjsko – Šaleška razvojna agencija SAŠA, Podjetniški inkubator Novo mesto, CS Škofja Loka and others.

Can SRIPs offer their support in the preparation of new project calls?

SRIPs members do work to identify new possible priority arias, but they can not influence how new project calls will be prepared, what will be their focus point, when they will be opened, etc. The partner organizations work to promote different identified strategic priority areas, but their influence on new project calls is very limited; their work can be included or not. As SRIP members play a key role in different areas, their contributions could make a difference, but are usually not included and their potential is currently overlooked.

Does SRIP TOP offer some kind of activities in terms of supporting educational activities

Yes, for instance GZS covers human resource’s part and in this respect offers a range of educational activities for members and wider.

Could PF become one of the horizontal areas of SRIP TOP?

SRIP TOP is finalizing the action plan for the next three-year long period. If members of SRIP TOP identify PF as one of the priority areas, it could be added to the next action plan after the next period. Especially, as PF already has specific domain ties to existing priority areas.

Are there currently any members of SRIP TOP that would fit the scope of PF

As mentioned, the smart plasma horizontal is involved in the processing of plant seeds. Artificial intelligence horizontal is involved in data mining. It is almost sure that other members members activities fall in the scope of PF (maybe agro-robotics).

How do you see that PF could be moved closer to the target groups

The faculty (FKBV) is invited to join the SRIP TOP. As different member faculties of the University of Maribor are already members of SRIP TOP, this should be a kind of simplified process. FKBV can then focus on areas like PF, that other UM member faculties do not cover.

Interviews with S3 managers – SRIP Smart Cities and Communities

Meeting date: 26th of May 2022: 9.00 - 10.30

Zoom platform for online meeting

Attendees:

Nevenka Cukjati - SRIP PMIS (S3 Smart cities and communities)

Jurij Rakun – UM, FKBV

Erik Rihter – UM, FKBV

Peter Lepej – AE-ROBO (partly present)

Agenda of the meeting:

To discuss the S3 regional specializations managers regarding the current and future inclusion of precision agriculture in SRIP PMsS (Smart cities and communities; SCaC); to identify the links between innovation strategies and the agricultural production sector through links at the level of technological development, implementation of regional innovations, support for the agricultural production sector and support for the education system with the possibility of directional training for agricultural needs.

Conclusions:

Agriculture is not the main sector

Agriculture is not the main sector of the SRIP PMiS, but with the new strategic plan that is under development this will be partly reshaped by covering areas like adaptation to climate changes, clean waters, green environments, etc. This indirectly affects and includes the area of precision agriculture.

How can SRIP PMiS support knowledge transfer in the field of PA and wider?

The role of the SRIPs is not to offer direct support, but to network specific actors in selected area. The domain for knowledge transfer therefore lies with the individual members of SRIPs. System of technological incubators and laboratories for Industry4.0 companies SRIPs do currently not offer this kind of services, as their role is primarily networking different actors. Like knowledge transfer, this is done by the resources and possibilities of individual partners.

Can SRIPs offer their support in the preparation of new project calls?

Directly no. Indirectly the members of the SRIPs identify potential priority areas which can be used in the project. The members of the SRIP are also invited to submit their ideas for new targeted project calls, but this is then filtered and possibly reshaped at the level of the Ministry in charge (Agriculture, Infrastructure, Education, etc.).

How do you see the educational system, could SRIP PMiS support in the preparation of new educational entity to support the PF?

Directly no, but with the support of different partners, different stakeholders, this could be achievable and welcome as PF technologies will play an important role in the future. So joint consensus regarding this should be accepted and based on these subsequent steps can be ensured to prepare the educational system.

Could PF become on of the horizontal areas of SRIP PMiS?

PF is a very important area and should be part of the SRIP PMiS. To start this task, different actors should first be identified and invited to cooperate. With this new partnership a strategic plan should be prepared and evaluated on the national level. Once this is approved, the partners should work, promote, spread their activities in support of PK / SRIP PMiS.

Are there currently any members of SRIP PMiS that would fit the PF scope?

There are multiple members of SRIP PMiS that would fit the scope of PF, for instance: among others, Optifarm and Login5 foundation for example could be invited to join the PF vertical.

How do you see that PF could be moved closer to the target groups?

One way of solving this challenge would be to prepare a model farm that uses new PF technologies that could serve as a demonstration tool for different actors like cooperatives, farming associations, industry, educational units, policy makers and other interested parties.